FIXED-TURNING® FOR THE HIGHEST QUALITY

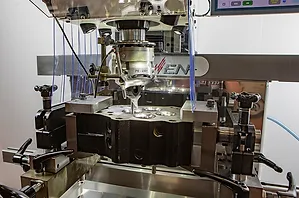

- numerically controlled axes driven by satellite roller screwsand servo-motors of the latest generation. A precision of the tool travelling by interpolation is measured in thousandths of mm.

- Z-axis ( 250 mm / 9.84’’) mounted on linear ways authorizing any cylinder head position while guarantying systematic balancing of the spindle. Increased work capacity and increased machining precision. A NEWEN® exclusive.

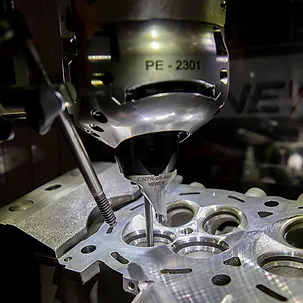

- NEWEN FIXED-TURNING® machining head featuring patented friction-free, pinion-free and maintenance-free kinematics, capable of machining with the highest degree of precision, year after year. Pilot centered and held by an original and particularly efficient crush sleeve system.

PRECISION IN EVERY COMPONENT AND DETAIL

- The spindle is built into in the machine head moving on the x,y axis owing to an air cushion. Automatic centering with programmable temporization. Automatic re-centering of the spindle with pneumatic

- Machining spindle mounted on special high precision bearing, greased for life. Powerful transmission via machined high precision spiral-beval pinion set.

- Machine parallels mounted on linear ways, greased for life, entirely protected. Simple, fast and efficient mechanical lock to ensure effortless positioning of any cylinder head.

- Electronic and electric components interconnected with quick plugs. Electronics entirely protected with stand alone suspended shock-proof cabinet. Electronics conceived and produced by NEWEN ®.

- Solid honeycomb-design machine upper ways confers stability, longevity and precision to the machine.

IMPROVED ERGONOMICS

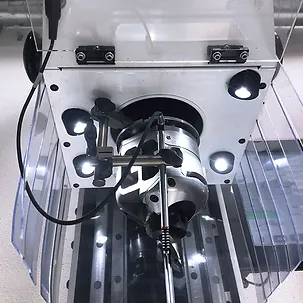

- SGC200M , palletizable™, 360° double-angle manual rollover clamping fixture. Allows quick positioning of most cylinder heads regardless of the valve guide angles. Also allows to simply raise cylinder heads to any desired level and to roll them over for various jobs. This patented system is quick, universal, very rigid, user friendly and does not put any stress on cylinder heads owing to its independent jaws and spherical collet clamping system.

- Built-in low-voltage multipoint lightning (LEDs) - cold light. The work area is paricularly well lit, the control of the finished work is improved and, consequently, the operator’s fatigue is reduced.

- 15’’ Fanless Industrial PC of the latest generation, IP65, with built-in flat touch-screen. A user-friendly and intuitive dialogue between the machine and the operator. Unlimited memory capacity.

- Control panel fitted with push-buttons, protected by an interchangeable lexan, and a multifunctional electronic wheel. Precision. Reliability

- Stress relieved welded frame coated with industrial resin, resistant to any chemical agent (High frequency stabilization during welding).