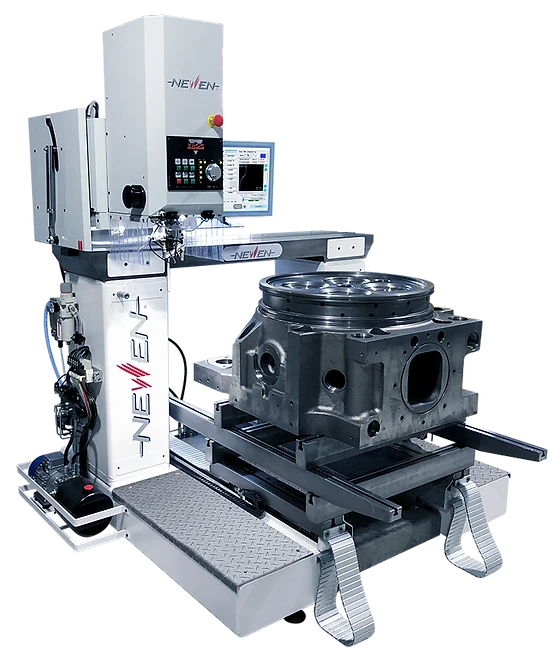

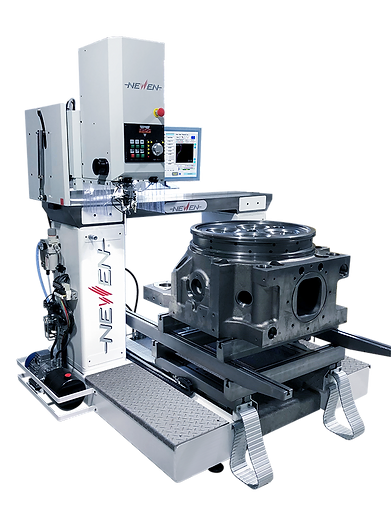

EPOC-VISION™ (Worldwide Patented • A NEWEN® Exclusive!)

EPOC-VISION™ The Most Universal Machine Ever Built Machine seats ranging in diameter from 13.5mm (.52’’) to over 240mm (9.45’’), from the smallest multi-valve motorcyle cylinder heads to the largest cylinder heads weighing up to 3 tons or more.

- machine stellite valve seats at high speeds with CBN inserts for unparalleled geometry - not permited by any other system.

- adjust actual valve seat angles at will, every one hundredth of degree.

- incomparable precision, flexibility and user friendliness.

- attain PERFECT SEAL between the valve seat and its valve, the first time, WITHOUT LAPPING.

- guaranteed concentricity owing to NEWEN’s Patented centering system.

- guaranteed circularity, within 3 microns per 100mm increment, even on valve seats as large as 200mm in diameter.

- unparalleled speed of execution : 1 to 3 minutes to machine a 170mm valve seat.

- constant speed guarantees perfection each and every time, particularly critical on large diameter valve seats - not permited by any other system.