FIXED-TURNING® VIR DIE HOOGSTE KWALITEIT

- numeries beheerde asse aangedryf deur satellietrolskroewe en servomotors van die jongste generasie. 'n Presisie van die werktuig wat deur interpolasie beweeg word gemeet in duisendstes van mm.

- Z-as (250 mm / 9.84'') gemonteer op lineêre maniere wat enige silinderkopposisie magtig terwyl dit sistematiese balansering van die spil waarborg. Verhoogde werkkapasiteit en verhoogde bewerking akkuraatheid. NEWEN® eksklusief.

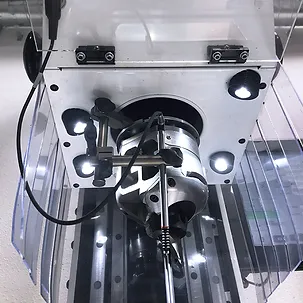

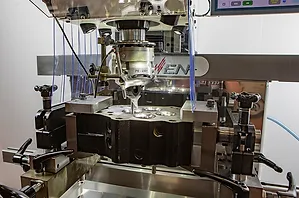

- NEWEN FIXED-TURNING®-bewerkingskop met gepatenteerde wrywingvrye, tandwielvrye en onderhoudsvrye kinematika, wat jaar na jaar met die hoogste graad van akkuraatheid kan bewerking. Pilot gesentreer en vasgehou deur 'n oorspronklike en besonder doeltreffende drukhulstelsel.

PRESISIE IN ELKE KOMPONENT EN DETAIL

- Die spil is ingebou in die masjienkop wat op die x,y-as beweeg as gevolg van 'n lugkussing. Outomatiese sentrering met programmeerbare temporisering. Outomatiese hersentrering van die spil met pneumatiese domkragte

- Bewerkingspil gemonteer op spesiale hoë-presisie laer, lewenslank gesmeer. Kragtige transmissie via gemasjineerde hoë-presisie spiraal-beval tandwielstel.

- Masjienparallelle gemonteer op lineêre maniere, lewenslank gesmeer, heeltemal beskerm. Eenvoudige, vinnige en doeltreffende meganiese slot om moeitelose posisionering van enige silinderkop te verseker.

- Elektroniese en elektriese komponente verbind met vinnige proppe. Elektronika heeltemal beskerm met alleenstaande opgeskorte skokbestande kas. Elektronika ontwerp en vervaardig deur NEWEN ®.

- Soliede heuningkoek-ontwerp masjien boonste maniere verleen stabiliteit, lang lewe en presisie aan die masjien.

IMPROVED ERGONOMICS

- SGC200M , palletizable™, 360° double-angle manual rollover clamping fixture. Allows quick positioning of most cylinder heads regardless of the valve guide angles. Also allows to simply raise cylinder heads to any desired level and to roll them over for various jobs. This patented system is quick, universal, very rigid, user friendly and does not put any stress on cylinder heads owing to its independent jaws and spherical collet clamping system.

- Built-in low-voltage multipoint lightning (LEDs) - cold light. The work area is paricularly well lit, the control of the finished work is improved and, consequently, the operator’s fatigue is reduced.

- 15’’ Fanless Industrial PC of the latest generation, IP65, with built-in flat touch-screen. A user-friendly and intuitive dialogue between the machine and the operator. Unlimited memory capacity.

- Control panel fitted with push-buttons, protected by an interchangeable lexan, and a multifunctional electronic wheel. Precision. Reliability

- Stress relieved welded frame coated with industrial resin, resistant to any chemical agent (High frequency stabilization during welding).